Behold the mighty multitool!

How To Use an Oscillating Tool

Use a Straightedge for Straight Cuts

Need to shave a little off a cabinet or a piece of trim because someone read the tape measure upside down? Use the oscillating tool to make a clean, precise cut and make the problem go away. Use a straightedge if you need a guide for the oscillating saw blade. Just watch that the blade doesn’t gouge the straightedge and go off-course.

Faster Flooring Prep

If you’re installing a new floor, a flush-cutting blade on an oscillating saw tool will slice through doorjambs like butter! With a scrap of flooring as a guide, the oscillating tool will make straight, clean cuts so that the new flooring will easily slip into place.

Cut Rusty Faucet Nuts

Sometimes you just can’t muscle off rusted-in-place faucet nuts with even the best basin wrench. And you can forget about using a reciprocating saw under the sink deck—there simply isn’t enough room. But you may be able to pull off the impossible by using an oscillating saw tool equipped with a high-quality bimetal cutting blade. Angle the tool against the nut and start it off at slow speed until it cuts a groove. Then increase the speed and keep sawing until you’re about three-quarters of the way through. Then break off the remaining portion with pliers.

Remove Trim Without Damage

Here’s a better method of removing delicate pieces of trim: Gently pry the trim away from the wall just enough to slip in an oscillating tool blade, then probe for the nails and slice through them with a metal-cutting blade. Fast, easy and no more splits. Use a scrap of sheet metal to protect the wall. Oscillating tool uses are endless!

Grout Removal

An oscillating tool does a great job of removing old grout from between tiles. It’s still tedious work, but unlike with other methods, you won’t damage the tiles or whip up a dust storm.

Trim Shims in a Jiffy

When you install a door, the usual way to trim the shims is to score them with a utility knife and then snap them off. It’s a slow way to go, and half the time, you push the shims out of place. Other times, they don’t break off cleanly. But an oscillating tool does the job perfectly. Quick, clean, no hassles.

Making Cuts in Cramped Spaces

Oscillating tools are perfect for tight situations where no other tool will fit. Use it to cut pipe in cramped quarters, to section out dry rot in a beam where a router or saw can’t reach, to quickly cut out damaged flooring and more.

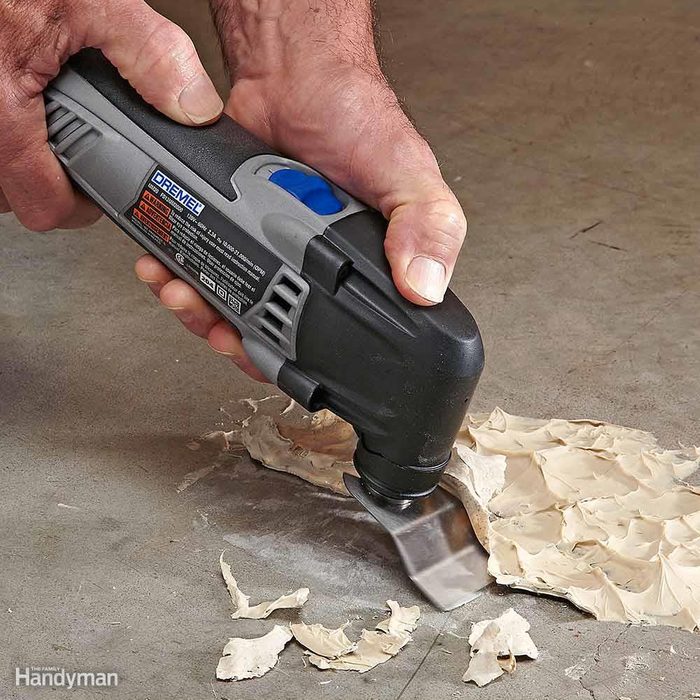

Scrape Away Gunk

Get rid of stubborn patches of dried construction adhesive, joint compound and other gunk without spending hours on your knees hacking with a putty knife. With an oscillating tool equipped with a scraper blade, you can slice it off in no time.

Remove a Toilet

Trying to remove an old toilet? Cutting off corroded hold-down bolts with an oscillating tool is a lot faster than trying to unscrew them. Ditto for the bolts that fasten the tank to the bowl. And if the bowl is caulked to the floor, you can switch to a scraper blade and slice right through the joint.

Remove a Towel Bar or Soap Dish

It’s easy to remove a broken or outdated surface-mounted towel bar or soap dish with an oscillating tool. Jam the blade into a corner about 1 in. deep. Then work it all around the fixture. Shove it in deeper and do a second pass around the fixture, cutting through all the adhesive and caulk.

Oscillating Tool Adapters and Accessories

Oscillating tool adapters give you more blade options. Sometimes, blades of one brand will fit on a multitool of another brand. But not always. So pick up an adapter that’s designed to suit your multitool. Most home centers carry only a small selection of blades and scrapers, but endless accessories are available online.

Oscillating Tool Blades: Round Vs. Straight

A straight blade is best for plunge cuts, where you stab the blade into the surface. For long, linear cuts, use a round oscillating saw blade. You’ll get cleaner cuts with the round blade if you make a shallow scoring cut first, then gradually deepen it with an oscillating saw.

In any case, keep in mind that heat kills blades. Occasionally, swing the oscillating tool blade back and forth out of the kerf to clean out dust. And don’t press so hard.

Oscillating Tool Scraper Blades

Scraper blades come in lots of styles: stiff or flexible, sharp or blunt, straight or offset. The long, thin version shown above is for digging caulk out of joints.

Grout Removal Blades

A carbide blade (about $25) is fine for small jobs. For larger jobs, a diamond blade ($40 and up) saves you money because it lasts two to three times as long. Both types come in 1/16-in. and 1/8-in. thicknesses to match grout widths. When you see sparks, you know that the outer edge of the blade is worn out, even though there may be plenty of grit left on the sides of the blade.

Extra-Wide Oscillating Tool Blades

Extra-wide blades like this 2-1/2-in. version are perfect for cutting round stuff like pipe because they don’t slip off a curved surface the way narrow blades do. For other jobs, narrower blades are usually best: They plunge-cut better and put less strain on the motor.

Oscillating Tool Metal Cutting Blades

Beware: Most blades sold in stores are meant for soft materials like wood and plastic. Cutting metal destroys them in a few seconds. For metal cutting, be sure to buy blades labeled bimetal.