Multiple Days

Intermediate

$101–250

Introduction

Need a great-looking bookshelf with classic lines by tomorrow? Using clever shortcuts and standard materials, you can build a bookshelf like this in a day.

Many of us love the idea of spending weeks on a complicated woodworking project, but few of us have the time. By taking some shortcuts, you can simplify the whole process of learning how to make a bookshelf and still produce handsome results.

This little bookcase showcases some of our favorite shortcuts: some save time, some minimize mistakes and others are low-effort paths to high style. It all adds up to a project you can build in a day, though finishing will add a few hours afterward. You’ll find all the materials in stock at most home centers.

Also, don’t forget to find out how to stabilize a bookcase on carpeting.

Tools Required

- Air compressor

- Air hose

- Brad nail gun

- Circular saw

- Cordless drill

- Countersink drill bit

- Drill/driver - cordless

- Dust mask

- Forstner drill bits

- Framing square

- Hearing protection

- Level

- Miter saw

- Orbital sander

- Router

- Safety glasses

- Table saw

- Tape measure

Materials Required

- See Materials List in "Additional Information"

- Wood glue

Project step-by-step (12)

Nail the box first, then screw

- Cut the 3/4-in. plywood box parts as shown in the cutting diagram.

- Note: The grain on the box lid (B) runs the “wrong” way, but it’s well below eye level, and only your pets will see it.

- To avoid splitting the plywood, drill pilot holes before you screw the box together.

- Tack the corners together with a brad nailer, then add screws.

- Pro tip: There’s no need for glue; three screws at each joint will make the box plenty strong, and you won’t have to deal with glue squeeze-out.

Keep it simple with adjustable shelves

- Use a scrap of pegboard as a perfect template to position the support holes.

- Mark the pegboard holes you want to use and label the end of the template that goes against the bottom shelf.

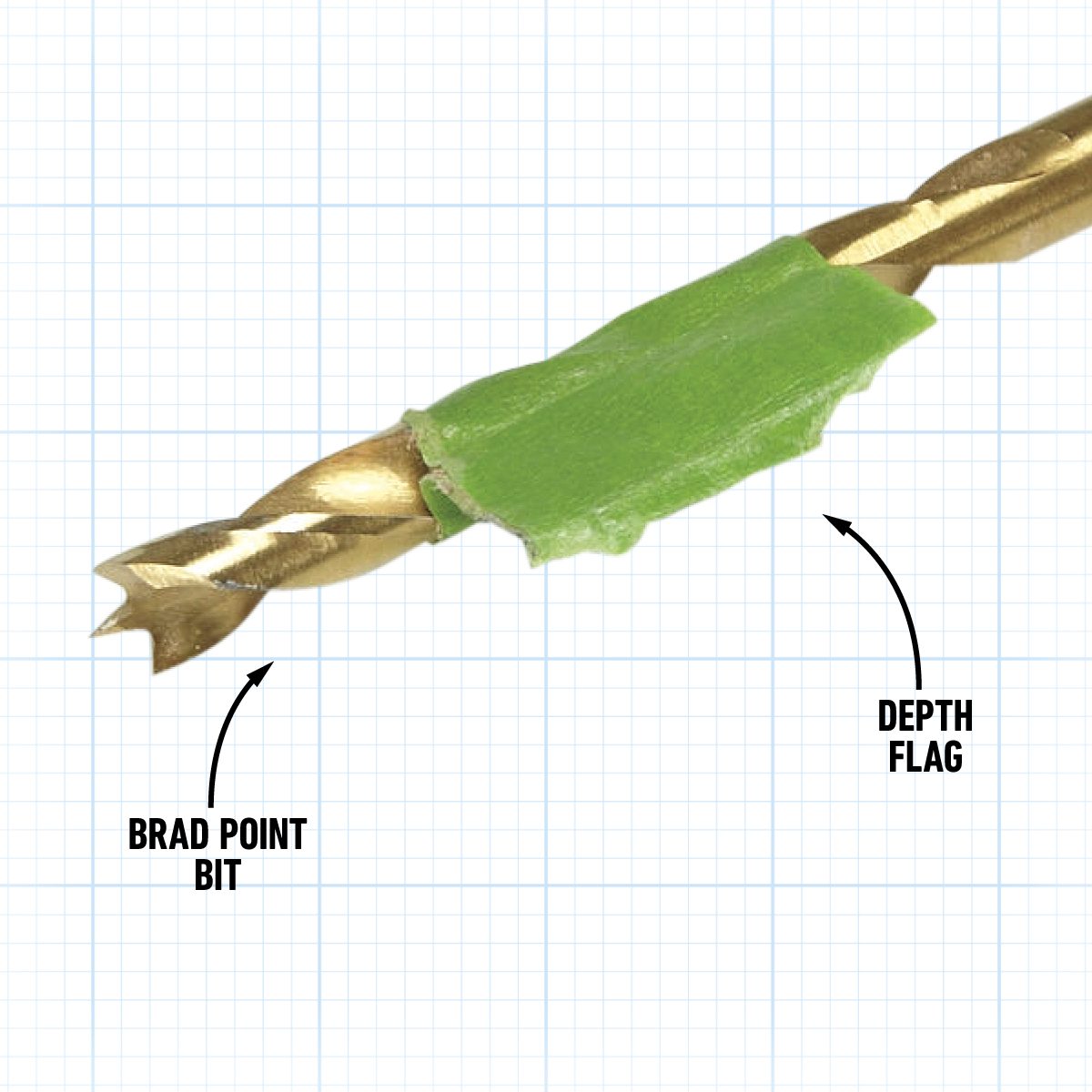

- Drill the shelf holes with a brad point bit.

- Pro tip: Wrap the bit with a masking tape “flag” to mark the depth of the hole.

Add shelf edging

- Spread a light bead of glue over the front edges of the shelves.

- Set the screen molding in place and “clamp” it with masking tape.

- Note: Pull the tape tight as you apply it.

Assemble corner stiles, then cut to length

- Start with corner stile parts (E and F) that are about an inch longer than their final length.

- Trim the ends to length.

Attach rails and stiles

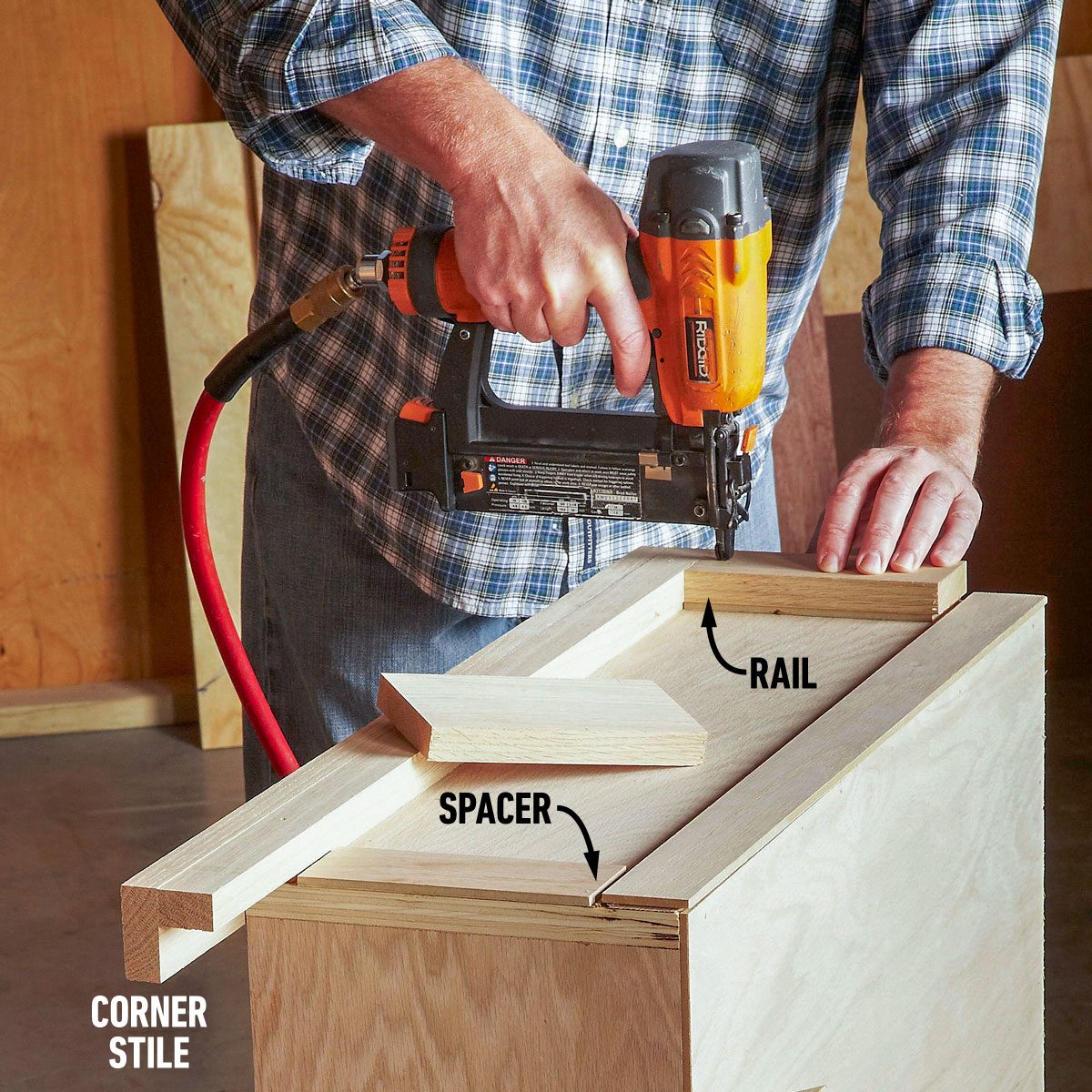

- Just glue and tack the spacers into place with a brad nailer.

- Glue and nail on the rails and stiles.

- Pro tip: Use only enough nails to hold the parts in place while the glue sets.

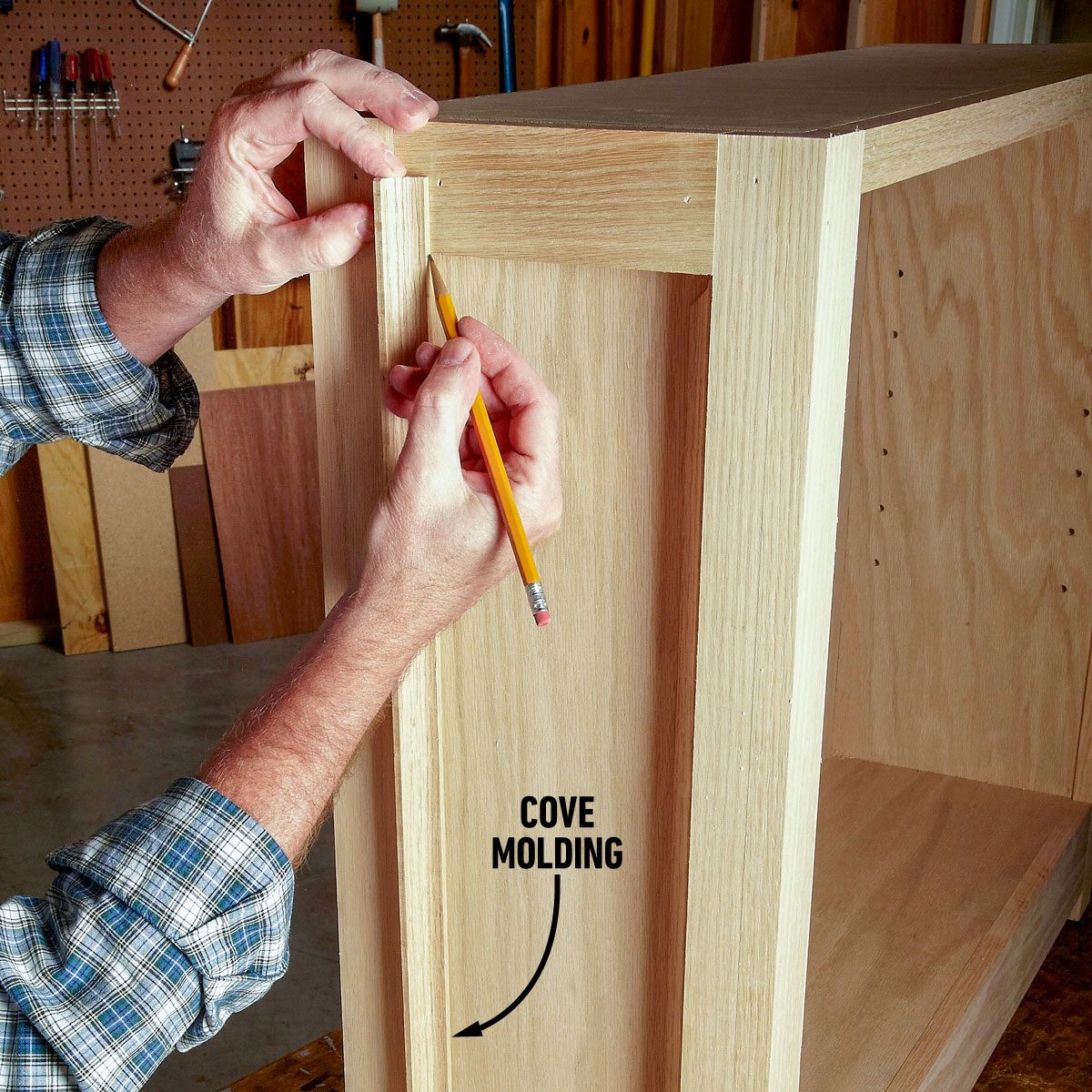

Add cove molding

- Miter one end of each piece and hold it in place to mark it.

- Pro tip: Cut the piece a hair long and test the fit. If it’s too long, take it back to the miter saw and shave off a smidgen.

Use basic boards for the base

- Glue and tack on spacers.

- Add the baseboards.

- Sand the joints flush and add the cove molding.

- Note: The base of the shelf unit is just boards topped off with cove molding.

Shape the top

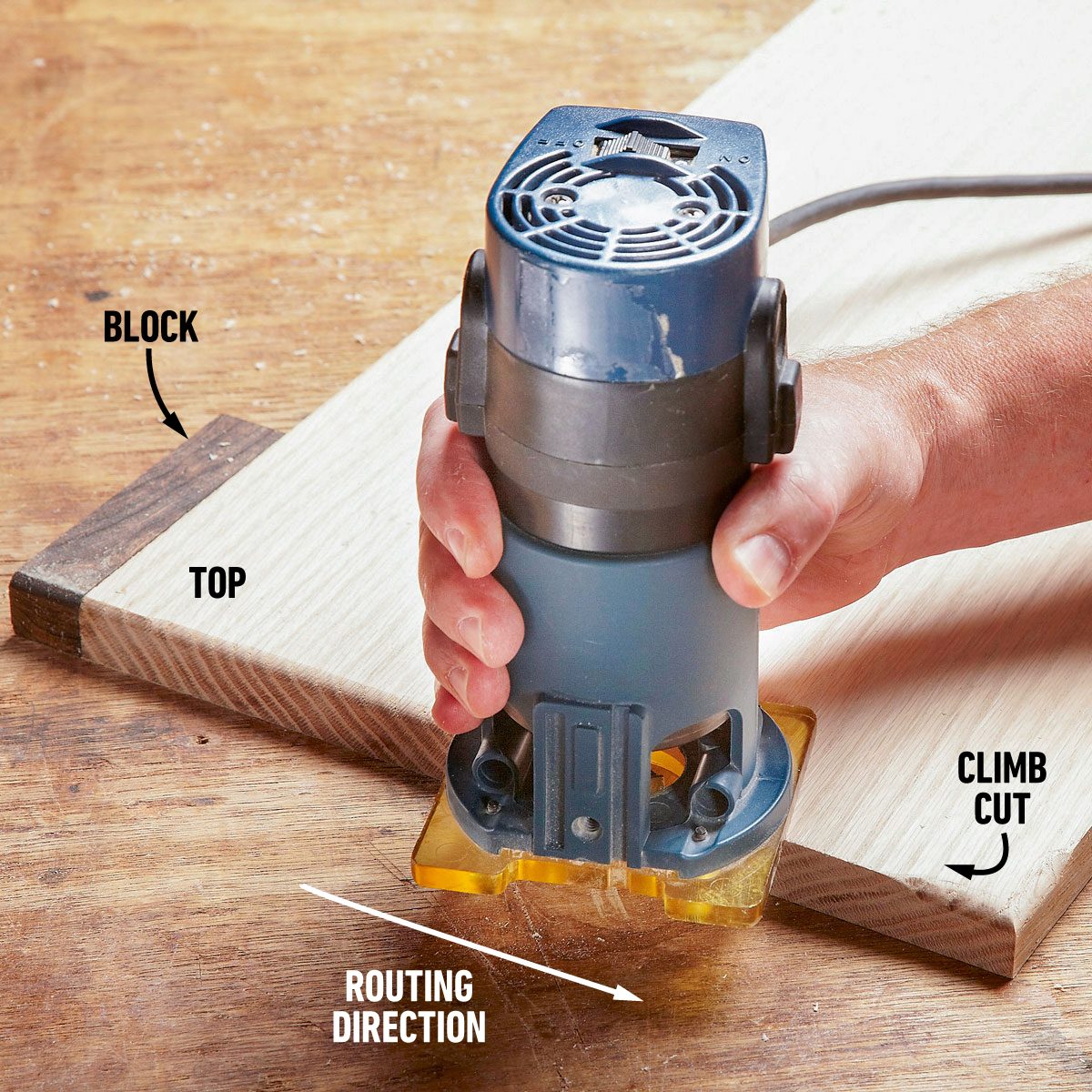

- Screw blocks to the back corners to prevent gouging as you begin and end routing.

- Pro tip: To prevent splintering at the front corner, make a reverse-direction “climb cut.”

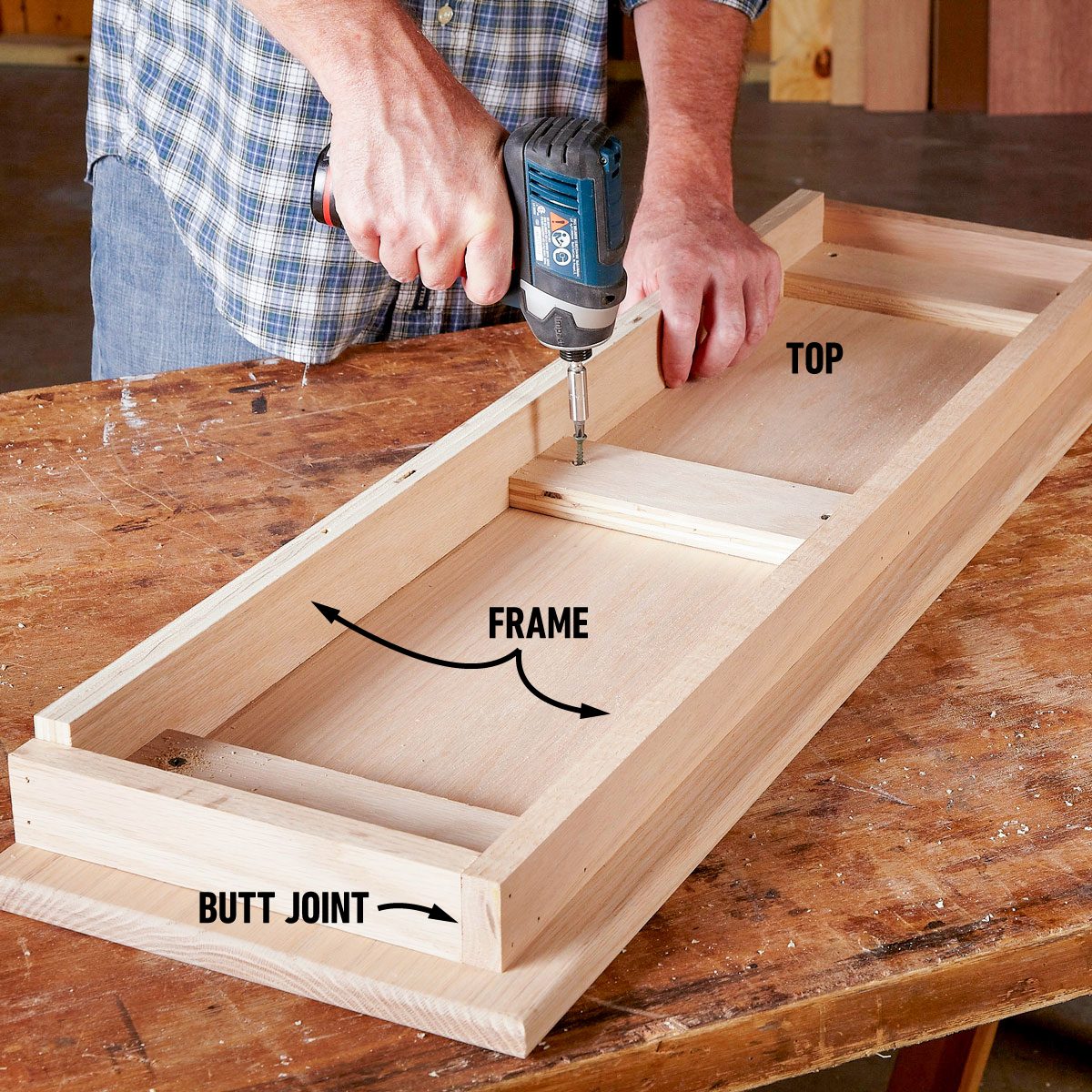

Assemble the frame

- Assemble the frame with glue and nails.

- Center the assembly and screw it to the underside of the top.

- Note: The square-cut butt joints at the corners of the frame make cutting and joining the parts a lot easier.

Make bead molding

- Round over both edges of a 1/2-in.-thick board.

- Sand the edges and then cut the completed moldings off the board.

Attach the moldings

- Trim the frame with cove molding and homemade bead molding.

- Glue in two layers of plywood filler blocks.

- Note: The blocks allow the top to be screwed to the shelf box.

Screw on the top

- Mount the top with screws only—no glue.

- Note: That way, you can remove it for easier sanding and finishing.

- Center the top and drive screws through the box lid and into the filler blocks. If you’re in need of a bookcase, then this wooden ladder shelf is a great option.