Horizontal boring, trenchless digging, directional drilling- whatever you want to call it, this just might be the solution you were looking for.

Horizontal Boring 101

Why Dig When You Can Bore?

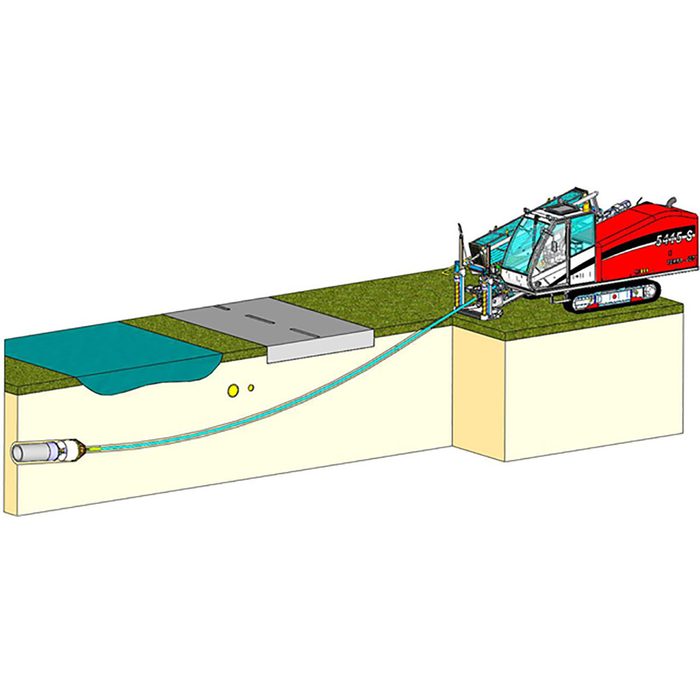

Directional boring rigs have the capability of pushing, pulling and rotating drilling rods underground with minimal disruption to landscaping, sidewalks, roads, etc. Directional boring is preferred over trenching when it comes to installing underground utilities such as water, sewer, gas, electric telephone, fiber optic etc. But it’s not as popular in the residential construction world, and that’s a mistake.

Underground Boring Basics:

Directional boring, sometimes called trenchless digging, or just “horizontal boring” is accomplished by piercing the ground with a drilling bit/head at a low angle. The bit is spun and pushed through the soil. Poles are contiguously added to increase the reach. Once the desired depth has been met the drilling tip levels out to maintain a horizontal bore. When the boring reaches its destination, a pipe, line, or conduit is pulled back through the hole.

Directional Steering Underground

Besides aggressive carbide teeth, drill heads are equipped with electronics that send out a radio signal. The signal is picked up by a receiver above ground, which detects the drill head’s location at all times. The person holding the receiver talks to the machine operator to tell them what direction to go. Some high–end machines have on-board system that allow the operator to see for themselves which way the bit is going.

Changing Boring Directions

This is a common cutting head configuration. It’s shaped sort of like a duckbill. When the head is spinning, it travels straight through the soil. When a directional change is needed, the person operating the machine will stop the pipes from spinning and just push them through the soil instead. The head will change direction depending on its orientation. There are a couple other methods, one using a bent end pipe and the other using a directional high-pressure water spray.

Drilling Pipe

The drilling pipe, also known as drill rod, drill stem, or drilling string, comes in many different lengths and widths depending on the size of the machine and the size of the hole required. This threaded pipe is similar to steel plumbing pipe but is designed to withstand high rotational torque. The pipe diameter ranges from 1 inch to 36 inches and larger. The pipes not only twist and push their way through the soil, they also deliver water, or other drilling fluid, to cool the drilling head and the electronics inside it, and in some cases, the water helps steer the head. Most machines automatically connect and disassemble the pipe.

Pulling

Once the drill has exited the ground at its targeted location, the drill head is removed and a “back reamer” or “expander” is installed in its place. Back reamers come in various sizes depending on what size pipe, line or conduit is being pulled. The pipe, line or conduit is then connected to the back reamer and pulled back towards the drilling rig.

Boring Machine Options

There are basically two kinds of machines, self-contained, and remote units. Remote boring rigs can be attached to a truck bed, trailer, or skid-steer. They are often powered by hydraulic pressure provided by a separate powered source. Self-contained rigs are more popular because they take less time to setup and can be maneuvered into tighter areas. Many machines are track driven and can easily navigate rough or unstable terrain. Drilling machines have outriggers that press into the ground to prevent them from being pushed back while driving the pipes forward. And some have onboard water tanks to cool the head.

So, Why Horizontal Boring?

Let’s say your customer is abandoning a well and connecting to city water. Why dig up and demolish the entire front yard and possibly loose beautiful trees that may be decades old. If the utility room is in the center of the house, directional boring makes even more sense. You can cut a 12-in. square hole in the concrete floor, and a good operator will be able to hit it, no problem. This is only one scenario. Think water drainage or connecting out-buildings to power and utilities. Basically, if you need a trench and there’s something in the way, directional boring may be able to save you a bunch of time and a pile of money.