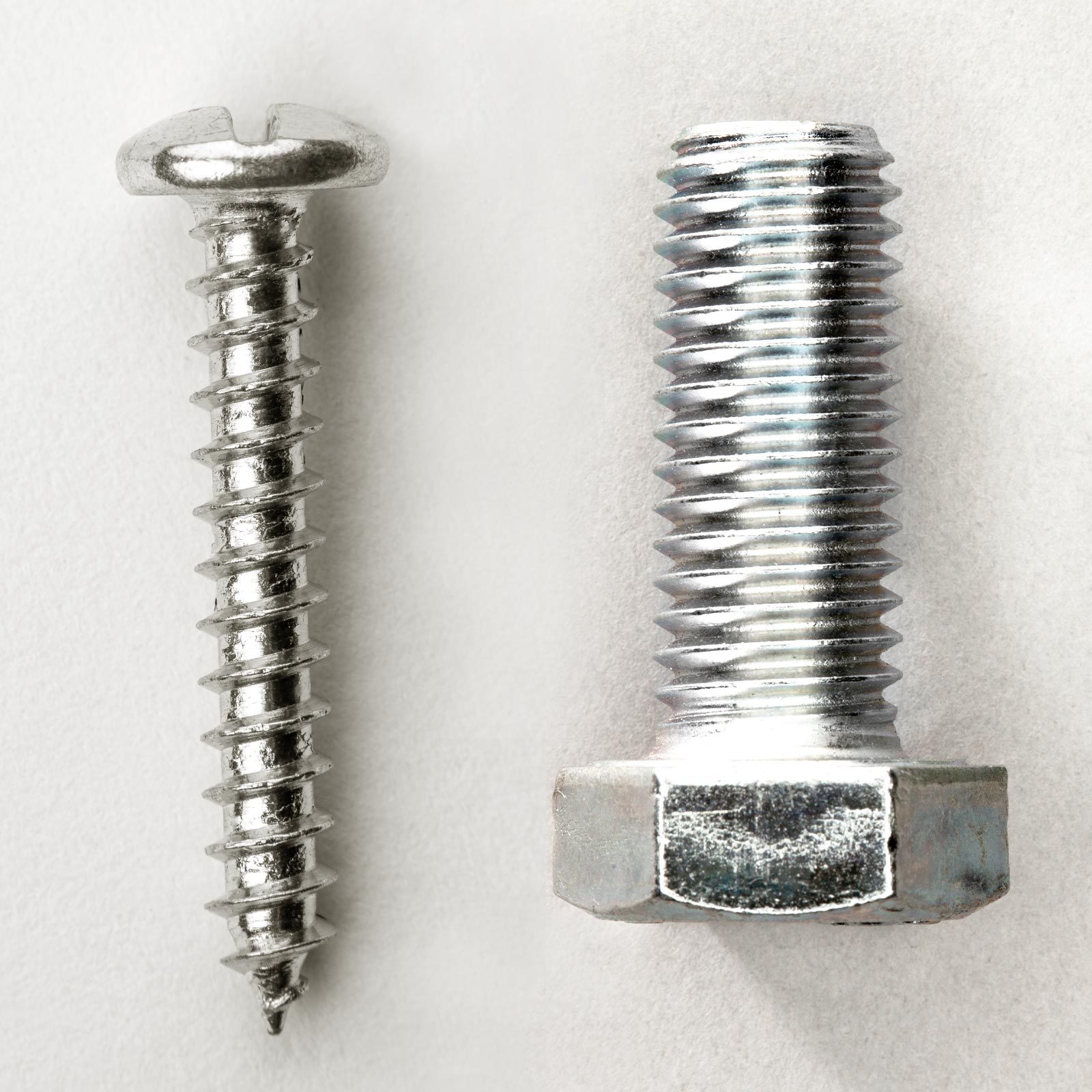

Screws and bolts may look alike, but they have different features and functions. Here's the lowdown on these essential fasteners.

Screws vs. Bolts: What’s the Difference?

It’s almost impossible to work on DIY projects of any size without using a screw or bolt. But while we all use these common fasteners, how many of us can really explain the difference between them?

To clear things up, we consulted with Patrick Holahan, director of engineering at Fastenal, and Drew Mansur, a professional contractor and co-founder and director of TileCloud, They laid out clear definitions for bolts and screws, explained what sets these fasteners apart from each other, and shared some tips for picking the right one for your project.

Let’s start by looking at screws and bolts individually.

On This Page

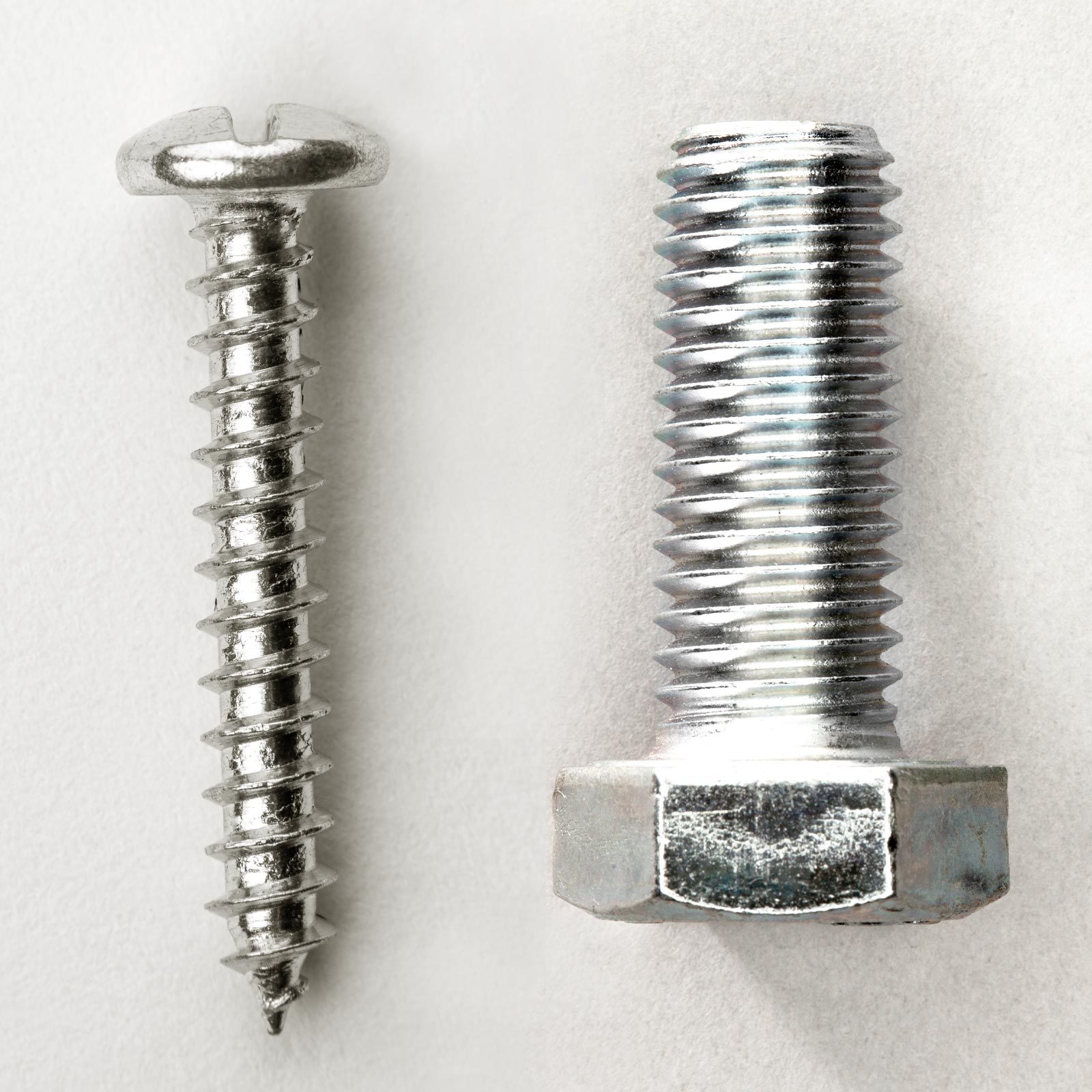

What Is a Bolt?

Bolts are threaded rods, often with a hexagonal head. They pass clear through the materials being joined, and are tightened by attaching a nut on their far side.

Nuts typically resemble small, hexagonal donuts, with threads in the inside of their hole. To be effective, the threads on the nut and bolt need to match.

To understand how a bolt works, imagine holding a hamburger. The burger, bun and all those toppings stay in place because your hands apply equal pressure from the top and bottom. Take away your fingers or thumbs, and that burger falls apart. In the same way, the bolt head and the nut squeeze materials together to create a solid joint.

As a construction pro, Mansur typically used bolts in situations where he needed a particularly strong bond, like in heavy load-bearing structures.

Holahan says this is why bolts are often available in higher strength grades than screws. “Bolts are used for carrying larger loads,” he says, “but require robust materials within the joints to handle the application forces.” (Translation: Don’t squeeze too hard on the hamburger.)

What Is a Screw?

By contrast, a screw doesn’t fully penetrate the joined materials and doesn’t use a nut to tighten. Instead, you turn the screw head to rotate the threads, synching with a pre-threaded hole or creating new threads in the material they move through. These two sets of threads create pressure, holding the materials tight.

While this makes screws simple to use, it comes with drawbacks. “The connection strengths are limited by the materials in which they’re installed,” Holahan says.

If the material crumbles instead of forming threads, the screw won’t tighten. This is why screws won’t hold in drywall unless they can bite into a stud or drywall anchor.

Screws vs. Bolts: What’s the Difference?

“Keep it simple,” Holahan says. “A screw is driven by the head and typically creates its own threads. A bolt is for heavy-duty applications and needs a nut or tapped hole of sufficient strength to function.”

Bolts:

- Must penetrate completely though both materials;

- Need a nut to tighten;

- Must have a hole pre-drilled in the joined materials;

- Applies force from the outside of the joined materials;

- Are often used for heavy-duty applications;

- Have flat ends.

Screws:

- Do not penetrate completely though both materials;

- Tighten by turning the screw head;

- Do not need a pre-drilled hole in the joined materials, although sometimes a pilot hole is recommended;

- Apply force from inside the joined materials;

- Often used for light-duty applications;

- Have tapered (pointy) ends.

Lag Screw vs. Lag Bolt

Of course, there’s always an exception! “Nothing is ever quite universal,” Holahan says.

There is perhaps no better example of this than the terms “lag screw” and “lag bolt.” Two names for the exact same fastener!

Lag bolts (or screws) are essentially large screws with hexagonal heads. Given their size and the materials they’re often used to join, the torque required to tighten them could strip out a slotted screw head. Instead, they use a more robust hex head.

While the tapered point and lack of nut place them in the screw category, that distinctive hex head is more typical of a bolt. “So technically,” says Mansur, “lag screw is the correct name, but [both] are commonly used.”

Which term is more prevalent often varies by region or trade. Luckily, most people on a job site or in a hardware store will understand either term.

Tips for Choosing the Right Fastener

“For DIYers,” says Mansur, “it’s key to consider the material you’re working with and the load it will bear.

“For heavy-duty jobs, like fixing a deck post, bolts are your best bet for their strength. For lighter tasks, like assembling a bookshelf, screws provide an easier and efficient solution.”

Also, he says, “Match the material of the fastener to your project. For example, choose stainless steel in outdoor environments to prevent rust.”

Holahan provided a few key considerations when selecting a fastener.

- Head type: Do you want the screw product to be flush in the application? Is there a certain cosmetic appearance you’re seeking? How noticeable can the fasteners be?

- Strength: Self-threading fasteners are case-hardened, so they can self-drill or self-thread in a variety of materials.

- Pilot holes: To avoid drilling pilot holes, consider self-drilling screws.

- Size: Diameter and length impact the choice of fastener. Look for sufficient length to provide proper holding power. Avoid having threads too close to the edge of a board or steel sheet, which can be a recipe for a failure.

- Materials and environment: If your project uses treated lumber or will be exposed to the elements, pick a fastener with an appropriate finish.

About the Experts

- Drew Mansur holds a degree in construction management. He co-founded a commercial tiling business and worked as a contractor before founding TileCloud.