Add beauty and value to your kitchen.

Our editors and experts handpick every product we feature. We may earn a commission from your purchases.Learn more.

Add beauty and value to your kitchen.

Our editors and experts handpick every product we feature. We may earn a commission from your purchases.Learn more.

Four Days

Intermediate

$2000 - $3000

Add beauty and value to your kitchen.

We’ve all seen ugly kitchens: Cabinets stained from decades of use, or outdated, cringeworthy styles that take us back decades. It sure would be nice to have new cabinets, but who has the money, or time? Remodeling not only costs a bundle, it can take your kitchen offline for weeks or even months. I’m an experienced woodworker, and I know building furniture from scratch takes time. Sometimes you need a faster solution.

What if you could give your kitchen a fresh new look for a fraction of the cost and disruption? You can! Refacing your kitchen cabinets is a DIY-able project that will give your kitchen a needed facelift, and there’s no need to rip out your old cabinets. As long as the “bones” are good, replacing the old drawers and cabinet doors will make your kitchen look brand new again.

You may wonder if you can use the old drawers and doors and just repaint them. Well, it’s possible, especially with custom or expensive cabinetry. Many people have veneered cabinets, though, and it’s better to start new. Will James, an experienced handyperson and virtual expert at Frontdoor home maintenance app, says it often depends on the finish and the condition.

“If veneer is peeling, moisture has most likely absorbed into the wood, and it should be replaced,” James says.

Ahead, I’ll walk you through my cabinet refacing project featuring medium-density fiberboard (MDF) drawers and doors, faced with a beautiful oak wood veneer. Follow along!

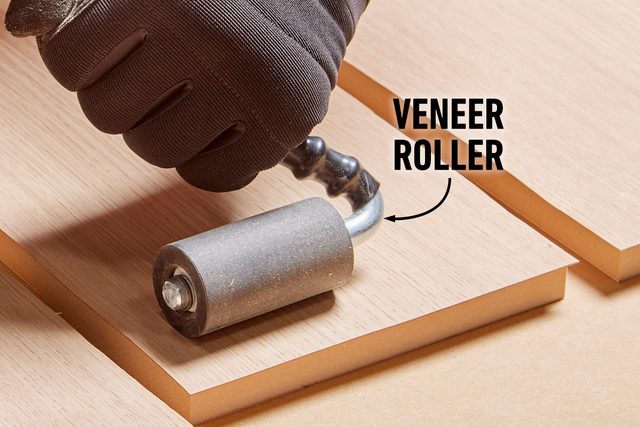

For this project, you’ll need basic hand tools like a drill, tape measure and utility knife, as well as a router. I also used some specialized tools that make refacing cabinets so much easier. These can be found online or at a home improvement center, and while some of them aren’t exactly cheap, they’ll help you get the job done in no time.

Edge banding is a thin strip of iron-on veneer used to cover the edges of doors and drawers.

Will James a versatile handyperson with over 12 years of experience and a passion for helping others. As a virtual handyperson expert at Frontdoor, James helps homeowners solve problems via tech-enhanced video chats, empowering others with his deep knowledge of multiple home maintenance issues.

Jay Cork is a woodworker, teacher and author at Family Handyman, where he loves giving new life to old things. Refacing cabinets is right up his alley.